Position Hold Versus Spring Return to Center Joysticks

Joysticks are an essential control component for many types of machines and equipment. In industrial and commercial sectors, their components must be precision-engineered to exact specifications. Having industrial-grade joysticks that are designed and made to the right application empowers the equipment to operate more safely and efficiently.

Spring return to center joysticks and position hold joysticks are two types that provide operators with greater control over their machinery.

As a rule, the application determines whether the joystick should return to its initial position when not actuated (by spring return) or whether it should remain in the last position in one or more deflection directions (friction brake, optionally also by detent positions). Most modern joystick models are equipped with a central spring. This spring returns the operating lever to the middle position for both deflection directions. The strength of the spring can be adjusted.

If the application requires position hold (friction brakes or detent positions), special models must be used, whose design is larger and more complex, but which are therefore more flexible for such adaptations.

SPRING RETURN JOYSTICKS

There are two types of spring return joystick mechanisms. A central spring, mounted at the base of the shaft, provides a uniform feel when deflected in any direction. Only one spring is in action whether operating on a single axis or dual axis. Dedicated spring designs, where there is one spring for the X axis and one spring for the Y axis (assumes a dual axis joystick) are also common. Joysticks utilizing dedicated spring returns are often categorized as “guided feel”. The spring tension felt by the operator when operating on just one axis (only one spring is engaged) is less than that felt when operating on both axes (both springs engaged).

Common Spring Return Joystick Applications

Applications that particularly benefit from these types of joysticks include the following:

- Food-processing machinery

- Process technology plants

- Hydraulic platforms and tail lifts on utility vehicles

- Aerial work platforms

- Airport service and apron vehicles

- Aircraft tractors

- Handling and assembly technology

POSITION HOLD JOYSTICKS

Position hold joysticks can maintain the joysticks lever position in two ways, “friction hold” or “detents”. In friction hold there is no spring, with detents, there can still be a spring return function. Friction hold allows the operator to smoothly maneuver the handle position anywhere within the operating angle of the joystick and have it remain in that position. The added torque is calibrated to be sufficient enough to hold the handle position in rough environments as well as allow for smooth, minute adjustments of the handle.

Joystick Detents

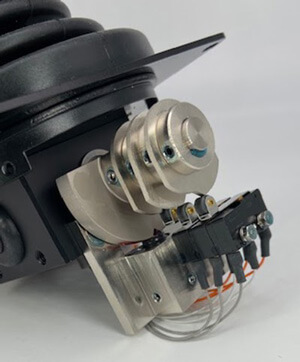

Detents are a different story. These require special modifications where the X and/or Y axis shaft of the joysticks gimbal assembly is extended, allowing machined cams to be attached. The cams are notched in accordance to where the position hold angle(s) are required. A spring-loaded bearing rides along the smooth part of the cam until a notch is encountered at which point the spring-loaded bearing “pops” into the notch. To the operator, a distinct tactile feel of engaging the detent notch is provided. In joysticks with spring return to center, the detent force can be adjusted to hold the handle in the notched position without the operator holding the handle, or, can be adjusted to allow the handle to return to center when released. In the larger joysticks, multiple detent positions are possible allowing specific positions of gradation (slow, medium, fast as an example).

Special note regarding detents and friction hold joysticks. A center detent is often utilized for position hold joysticks that use friction (increased torque) as the operator has no “feel” for the center position. In spring return to center joysticks, the center position is obvious. With a center detent in a friction hold joystick, the center position once again becomes obvious.

Common Position Hold Joystick Applications

Friction hold is ideal in applications that include panel mount and joystick integration as well as agricultural machinery, material handling equipment, and off-road vehicles. Applications that particularly benefit from these types of joysticks include the following:

- Compactors and asphalt rollers

- Material handling equipment

- Agricultural tractors and harvesters

The ‘friction-hold’ mechanism allows operators to maintain a constant speed when the joystick is released. This leaves the operator to focus on other machine and equipment controls. He or she may, for example, be able to focus on steering and monitoring the work progress. The operator can set the speed of movement and then focus on the steering of the vehicle to achieve optimum compaction of the surface it is traveling over, for example, asphalt or soil.

CUSTOMIZATIONS TO JOYSTICKS

In addition to selecting a position hold or spring return to center joystick, there are several other precision joystick features to customize handling including mounting styles and the number of axes. Each of these requires additional specifications for your application to achieve optimal performance.

Before jumping to choose a specific joystick based on price, it’s important to have a full breadth of knowledge on what will give you the best return. Our application engineers are well versed in the factors that should go into purchasing a new joystick or replacing parts. With so many functions for joysticks, including spring return to center joysticks, it may be best to consult with an expert.

Custom Joystick Designs

P3 America offers a range of position hold and spring return to center joysticks. Our joysticks provide several features that are fit for your project. If, however, you are looking for additional capabilities to meet certain specifications, our specialists are experienced in delivering custom-engineered designs and customizations to meet your needs.

Precision Positioning Products (P3) America has been providing automation and electromechanical products and services since 2004. Our staff has experience in the field as far back as 1983. For more information on how our team can help support your joystick project, give us a call at (512) 337-7336.

Recent Posts

-

Absolute vs Incremental Encoders

Systems involving motion, especially industrial processes, are tremendously complex. Designing an …Sep 8th 2020 -

Position Hold Versus Spring Return to Center Joysticks

Joysticks are an essential control component for many types of machines and equipment. In indus …Sep 8th 2020 -

Finally! Customer-Programmable Potentiometers

By programming potentiometers specifically for your application, these components can be made t …Sep 4th 2020